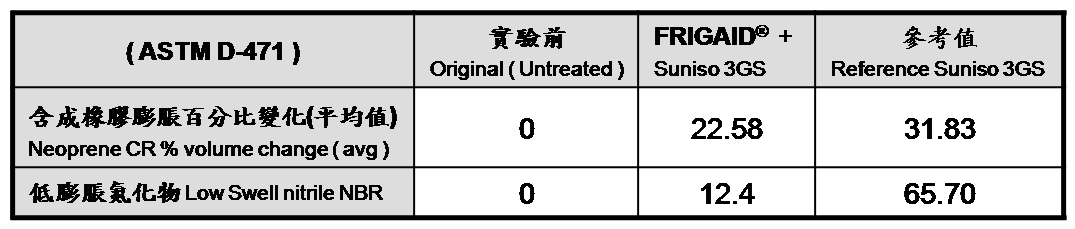

SEAL MATERIAL COMPATABILITY TESTING ( 密封件材料相容性測試 )

FRIGAID®添加可減低合成橡膠之膨脹達29%,氮化物之膨脹達81%。

FRIGAID® 不僅可以安全地使用,同時亦讓這些密封件材料之壽命延長。

FRIGAID® addition reduced welling in the Neoprene by 29%, in the Nitrile by 81%.

FRIGAID® not only can be safely used, it provides life extending benefits to these seal materials.

密封件材料樣品被浸泡到Suniso 3GS油以及3GS油加上FRIGAID®中。隨即比較兩種材料的體積變化百分比(膨脹測試)。

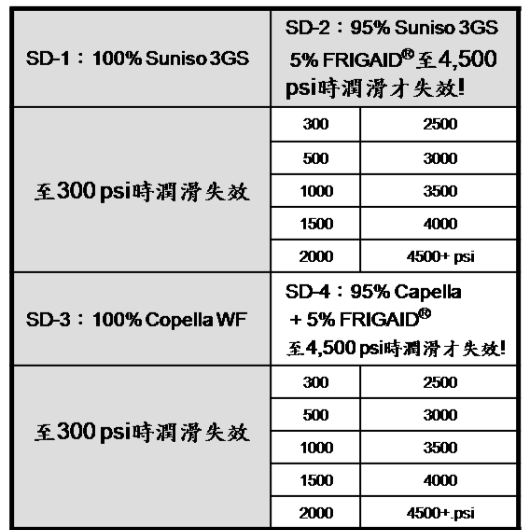

LUBRICITY EVALUATION 潤滑測試 ( ASTM D-3233-73 )

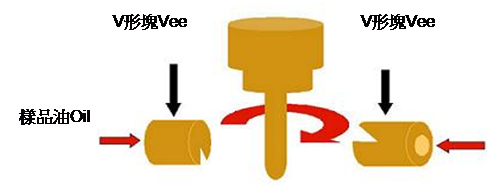

Falex 細棒與V形塊測試測量潤滑劑之承受負載能力。根據ASTM D-3233-73『液狀潤滑劑之極限壓力性質』Falex測量法執行。

這項測試採用一支細鋼棒在290rpm迴轉速下和兩個V形塊相抵產生四個線狀接觸,鋼棒和V形塊浸在樣品油裡,而在其中冷媒起泡沫狀,模擬出壓縮機在負載下之運轉情形。V形塊對鋼棒施壓,直到最終鋼棒無法再迴轉而潤滑失敗為止。

The test employs a steel pin rotated at 290 R.P.M. against two vee blocks to give a four-line contact. The pin and vee blocks are immersed in an oil sample through which Freon is bubbled to simulate compressor-operating conditions. Load is applied to the rotating pin via the vee blocks until the oil sample fails.

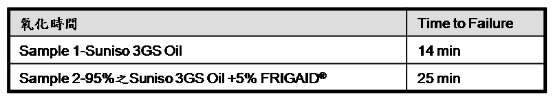

OXIDATION RESISTANCE TESTING 抗氧化測試 ( ASTM D-2272 )

注入FRIGAID®可增加冷凍油抗氧化性達78.5%,保護壓縮機免於磨損

Increased the oil’s resistance to oxidation by 78.5%. Increased resistance to oxidation provides extended wear protection for compressor components.

冷凍油樣品暴露在90 psi 之氧化環境下,然後加熱至華氏320℉。冷凍油樣品吸收氧氣(氧化)後,壓力下降。