FRIGAID® 節能工作原理 (FRIGAID®Working Principle )

1.lmprove heat transfer capacity in the evaporator and condensing coil.

(提升蒸發器及冷凝器之熱傳導能力)

2.Increase lubricity and reduce friction by 1500%.

(提升潤滑能力及降低磨擦損失1500%)

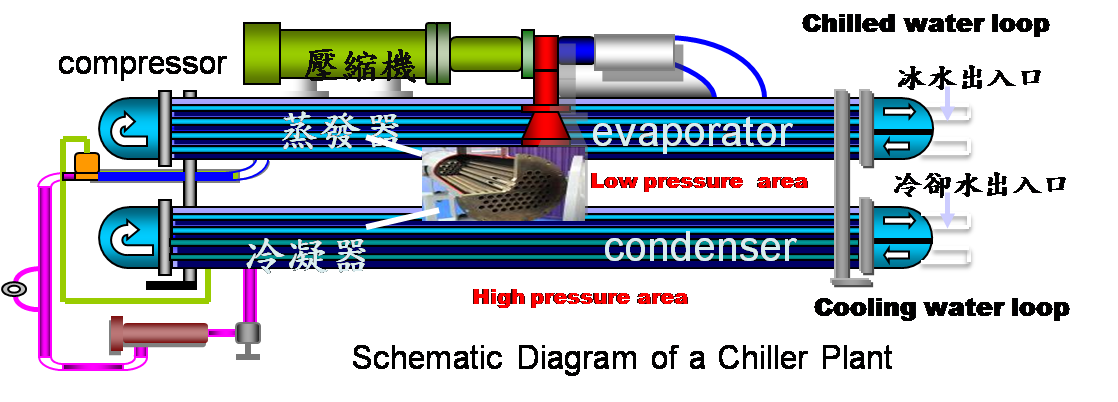

金屬有微小的晶格間隙,而冷凍空調系統中,如冷凝器、蒸發器,管路中,其金屬表面會積滯大量油膜組織,此油膜組織不僅阻礙熱的交換作用,降低空調系統的效率,更大大的增加起動電流,浪費電力。

The tiny lattice cracks existing at the tube material can cause oil and carbon deposits to be trapped, and thus making its heat transfer performance to degrade. This can also cause start-up demand current to increase significantly.

由於FRIGAID®的電磁效應引起金屬表面熱傳性質的改變。在冶金熱力學及表面化學上是一大突破。 FRIGAID®的電磁分子嵌入粗糙金屬表面的微小晶格間隙中,造成金屬熱傳速率的提昇,並且有效地分離釋出沈積在金屬表面之積碳、污染物與積滯的油漬,使金屬表面潤滑能力提高。

Highly polarized at one end, the FRIGAID nano-particles has a strong affinity for metal and forming a chemical bond with the tube interior surface, forming a very thin layer of molecules which replaces the oil layer and enhancing the lubricity.

依據美國空調學會1994研究報告指出,中央空調主機長運轉性能劣化時常見徵兆及問題為: 積碳、汙染物、積滯的油漬

在壓縮機運轉過程中,積碳、汙染物、積滯的油漬將停留於冷媒側系統內,造成熱傳效率下降,所能提供之冷凍能力也將大幅減少,亦會造成壓縮機作功增加,主機性能COP降低,kW/RT耗電量增加。

Based on the ASHRAE research report in 1994, HVAC systems can suffer performance degradation from : Carbon Deposits, Contaminants, Stagnant Oil Causing the chillers with lower COP and higher kW/RT power consumption.